Strategy February 11, 2026

How Made-To-Order Apparel Levels Up Promo Campaigns

Though it comes with plenty of challenges, made-to-order apparel reaps unique benefits to the promo companies able to offer cut-and-sew customization.

Key Takeaways

• Fully custom cut-and-sew apparel can help distributors and suppliers win high-value business by delivering products that don’t exist off the shelf, boosting differentiation and customer loyalty despite higher upfront complexity.

• Custom manufacturing enables tighter control over design details, color consistency and fit, making it especially valuable for large programs, brand storytelling and uniform applications where cohesion matters.

• While custom projects often take longer to develop, direct factory access, domestic production and in-house capabilities can shorten timelines, improve speed to market and solve last-minute or highly specific client needs.

An executive vice president from Toyota North America wanted to give his employees a replica of his favorite piece of outerwear: an old-school racing jacket with all the bells and whistles, from colorblocking and contrast piping to multiple pockets and hidden adjustable elastic for a perfect fit.

There weren’t blanks available to match the automotive exec’s vision, but Cary Heller, vice president/partner of Michigan-based supplier All USA Clothing (asi/30171) was confident his team could build something from scratch. “I literally took the jacket off his back,” says Heller, so All USA’s production staff could reverse engineer a preproduction sample in a day.

All USA Clothing (asi/30171) created more than 2,000 custom jackets for Toyota North America from scratch by reverse engineering the client’s favorite jacket.

Toyota North America was so impressed that they were ready to place an order right away, even though Heller couldn’t quote an exact price until he’d launched production for a short run in one size. “They wrote an open purchase order for whatever 50 would cost,” he recalls. “So, we made 50 in size medium, and they were so expensive, I thought they were going to say, ‘Hit the road, Jack.’ But they didn’t bat an eye.” All USA Clothing, which specializes in rugged workwear and American-made branded merch, ended up manufacturing more than 2,000 of the jackets for the car brand.

Suppliers in the promotional products industry have vast catalogs of SKUs – T-shirts, hoodies and other apparel in just about any cut and color you could want. Those items can be decorated and personalized, and occasionally the design elements can be tweaked.

Sometimes, though, that isn’t enough. Enter the “think-outside-of-the-boxers,” as Nilo Jones, the co-founder and head of design for upstart made-to-order apparel supplier Thread Farm (asi/91145), calls them.

“It’s really up to your wildest dreams, and we can make it happen with all our capabilities.” Tricia Parsons, Kotis Design (asi/244898)

Whether it’s building brand buzz with unique influencer merch, filling a gap in the marketplace or solving a very particular design problem, custom design services are a differentiator. “You have to set yourself apart from everybody else,” says Dilip Bhavnani, chief operating officer of Counselor Top 40 supplier Sunscope (asi/90075). “If you’re selling a generic product that everybody else can sell and access … it’s a race to the bottom.”

And though fully custom merch comes with plenty of challenges and upfront effort, once you’ve surprised and delighted a client with a solution that fits their needs and perfectly matches the vision in their head, they’re hooked. “You’ve now provided a customer with a product they can’t get anywhere else,” says Max Feldman, division president of EdwardsX, the custom division of Counselor Top 40 supplier Edwards Garment (asi/51752). “They’re locked in. The switching cost for that client becomes really high and complicated. Custom can be a real pathway to continuous revenue.”

‘The World’s Your Oyster’

Tricia Parsons and Terrence Henderson of Counselor Top 40 distributor Kotis Design (asi/244898) have seen custom projects they’ve worked on out in the wild – sported by fellow passengers on an overseas flight, perhaps, or as a highly marked up listing on eBay. It’s a testament, they say, both to the trend research they do before embarking on a project, as well as the collaborative ideation process with clients. The level of detail can get as granular as adjusting the amount of batting in a jacket, altering the placement of pockets or tweaking the overall fit of a garment.

“It’s really up to your wildest dreams, and we can make it happen with all of our capabilities,” says Parsons, design director at Kotis. “The world’s your oyster.”

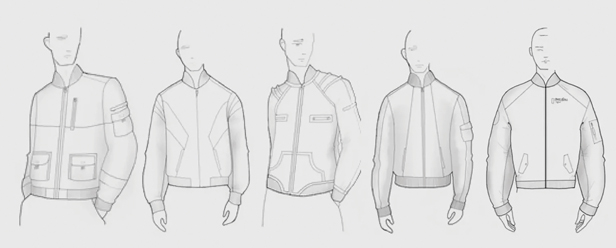

Kotis Design (asi/244898) sketched out several design options for a custom reversible bomber jacket requested by game studio Bethesda that was sent out to influencers and went viral.

Those capabilities were evident in a 2023 project for video game studio Bethesda, which asked Kotis to create a bomber jacket for the launch of popular game Starfield. After searching for an existing style, the team determined the jacket would need to be built from the ground up to achieve the client’s desired look. Kotis was able to create a custom-fitted flight jacket with a slew of decoration details, including a reflective full back print and individually embroidered gamer tags on the right chest for jackets sent out to individual influencers. The biggest wow factor, though, was the allover star print lining – and the fact that the jacket was reversible to display that showstopping element.

“It went viral,” says Henderson, technical designer at Kotis. “I have friends who played the game, and they were talking about seeing this cool jacket, and I’m like, ‘That was me.’”

Telling a Cohesive Brand Story

Another area where custom cut-and-sew shines is color consistency. “If you buy traditionally off the shelf from the big boys in our industry, you know every time they do a different dye, there’s a slightly different color,” Bhavnani says. This can cause unintended slight color variations.

That can be a particular problem when it comes to large program business, where exact color-matching is crucial to conveying a cohesive brand story, Feldman says.

Edwards Garment worked with Michigan-based distributor Ann Arbor T-shirt Company (asi/122210) creating uniforms for Sun Communities, a property management business with thousands of employees ranging from front desk clerks to mechanics to grounds crew. “They needed a wide assortment of product to fit their entire workforce, but they needed to have it all look cohesive,” Feldman says.

Edwards Garment (asi/51752), through its EdwardsX custom division, created these custom uniforms for Sun Communities.

Taking a piecemeal approach and sourcing styles from multiple suppliers would likely have resulted in navy blues that weren’t in perfect formation and a range of greens that were ever so slightly off. “What we’re able to do is create an entire assortment of dozens of products that all have the same color,” Feldman adds.

And though the entire process of creating a 100% custom piece – from ideation to preproduction to full production – is typically significantly longer than simply adding a logo to a ready-made blank, there are “counterarguments to that,” Feldman says. For instance, he adds, Edwards Garment once received an order for 72,000 black jackets for the Meijer grocery chain and was able to deliver in 10 weeks. Trying to source such a large volume of blanks from one supplier might put a distributor at odds with inventory levels and production schedules. “Because we have direct access to the factories and can find the fabric and trims and mock it up right away, sometimes custom can be quicker” than traditional bulk orders, he says.

Becoming Your Client’s Hero

Speed to market was actually one of the main reasons Winston-Salem, NC-based decorator SE Logo Wear brought its cut-and-sew dye sublimation in-house. A little over a decade ago, SE Logo Wear was fulfilling custom caddy bibs for the PGA Tour, working with overseas vendors and becoming frustrated by factory mistakes and other supply chain snarls.

“Our challenge was that we couldn’t get the product quick enough,” says Charlie Grubb, president. “After we had a couple of letdowns, I decided that we were just going to bring it all in-house, and the PGA Tour contract helped facilitate the investment into equipment and staffing.”

The custom cut-and-sew program has continued to grow since then, with SE Logo Wear devoting about a dozen of its 60-plus staffers to the department. One market that’s proved lucrative is youth sports, since rosters are often fluid until the last possible moment. Team organizers are often willing to pay a little more to have custom dye sublimation jerseys made domestically, Grubb says, because if a student athlete joins the team at the eleventh hour, SE Logo Wear can expedite getting that extra personalized jersey ready to go in time for the first game of the season.

An Expert Partnership

For newbies, getting started with made-to-order merch can be daunting. However, the suppliers already immersed in this world are more than eager to become a trusted partner and resource to interested distributors.

Sunscope, which a few years ago launched a custom apparel division known as DiLA (Designed in Los Angeles), has a 6,000-square-foot showroom, featuring over 3,000 swatch cards, at distributors’ disposal, according to Bhavnani. “We have distributors with end-users visiting us regularly,” he adds. “They come in, and we’ll custom design something for them there and then. It’s pretty awesome.”

In addition to assisting with the creative process, suppliers that specialize in custom work can help hammer out technical details, quality control and ensure the end-product meets compliance standards. They’re also on hand to explain when an idea simply isn’t feasible, like when a customer wants to replicate a retail brand’s unique products. “That starts to get into very dangerous territory,” Feldman says, adding that though suppliers can create garments that are inspired by retail pieces, an exact match of a very specific item already in the marketplace could hew quickly into copyright infringement.

Thread Farm (asi/91145) offers a variety of apparel decoration techniques on its cut-and-sew custom garments, from silicone to fabric embossing.

Another consideration is fit and durability. Designers can steer clients away from fabrications and decoration methods that might be uncomfortable or more prone to wear and tear. For instance, Thread Farm worked with a brand on a project tied to the release of a new caramel-covered snack. The company wanted a track jacket with a silicone drizzle effect over the shoulders to mimic the look of the sticky sweet treat. “I had to keep explaining that silicone is thick and rubbery,” Jones says. “Imagine putting a huge silicone piece on your body. It’s just not going to work. It’s going to be uncomfortable.”

Instead, Thread Farm suggested that the distributor and its client try a smaller treatment less prone to wear and tear, since it wouldn’t be crossing the jacket’s seams.

“Design is a set of problems to solve, and getting something from a 2-D rendering to 3-D is one of my favorite things to do,” Henderson agrees. “We have to consider fit, we have to consider function, we have to consider fabric. Trying to hold it all together is a tightrope walk, but it’s important so that when the finished product gets to the customer, they’re proud to wear it, or display it for their team or sell it to their own customers.”

3 Challenges to Going Custom

Producing fully custom apparel opens up exciting creative possibilities, but it also introduces a new set of hurdles. Here are three of the most common concerns.

1. Longer Timelines

The length of time it takes to create merch from the ground up can vary depending on the level of customization involved and whether the client requires preproduction sampling. On its website, Counselor Top 40 distributor Kotis Design (asi/244898) shares a general timeline for a custom project to help give clients an idea of the process, with art taking around 15 days, two rounds of sampling adding another 30 days, production itself taking 30 to 40 days and ocean transit adding 30 more days. (Air transit, while shorter, adds to the overall cost and carbon footprint of a project.)

For the procrastinators and panic buyers, those timelines simply won’t work. “We’ve had to decline many orders where our clients said, ‘Hey, I need this next week,’” says Celil Kes, owner of Thread Farm (asi/91145).

2. Increased Prices

For buyers not accustomed to everything involved in going fully custom, there can be a certain amount of sticker shock. To combat this, distributors should take the time to educate customers on the benefits of a completely custom product (and weed out reluctant clients early in the process to avoid wasting resources on spec work that doesn’t come to fruition).

Consider, however, that offering something totally custom can be a savvy tactic to prevent clients from trying to comparison shop, notes Dilip Bhavnani, chief operating officer of Counselor Top 40 supplier Sunscope (asi/90075).

3. High Minimum Order Quantities

Cut-and-sew factories typically require higher quantities than the 24- to 48-piece minimums promo apparel end-buyers are accustomed to. But made-to-order apparel suppliers say the MOQs aren’t out of reach. Tricia Parsons of Kotis notes that the distributor can typically do fully custom orders with a 144-piece minimum. “That’s actually pretty approachable,” she adds.

Kes and Nilo Jones of Thread Farm say they’ve been able to leverage long-standing factory relationships to offer custom goods with runs as low as 50 pieces. “For custom,” Jones adds, “that’s just unheard of.”